- A new report out of Japan says that Nissan could have next-generation solid-state electric vehicle (EV) batteries in production by 2028

- Solid-state batteries promise longer ranges and lighter weights, which could solve many of the problems of a challenging transition to EVs

Nearly every automaker is hard at work on a next-generation battery technology that could revolutionize electric vehicles (EVs). A new report says Nissan may get there first.

The news isn’t a surprise — Nissan has long discussed its progress toward what engineers call “solid-state batteries” more publicly than most automakers. We’re not clear on whether Nissan is further along than its rivals, or just talking about its efforts more.

Related: What is a Solid-State Battery?

Either way, Japan’s Nikkei news service reports that the company “has taken a major step in the development of next-generation all-solid-state batteries for electric vehicles, creating prototype cells that look set to double current driving ranges.”

InsideEVs adds, “Nissan’s solid-state battery cells have now reached performance targets to enter mass production.”

Lighter Weight, Longer Range from Ceramic Materials

- Today’s EV batteries use a gel-like slurry to store electricity, which is extremely heavy

- Dry batteries with solid cores promise much better performance, but are hard to mass produce

Batteries work by passing electrons from a positively charged pole, called a cathode, to a negatively charged pole, called an anode, through a substance called an electrolyte. The lithium-ion cells commonly used in EVs, laptop computers, and cell phones today employ a dense gel electrolyte.

Much of their weight is, essentially, water.

The gel can be volatile, contributing to fires in damaged batteries. It requires expensive, rare-earth metals that have become a flashpoint in global politics.

Solid-state batteries use a lightweight ceramic-like electrolyte instead. They’re lighter, without all the water. Some designs use fewer exotic materials, potentially easing global political tensions over rare earth metals.

Most importantly, they hold more energy. That could mean EVs with 600 miles of range, halving demand for chargers nationwide.

Related: How Solid-State Batteries Could Shape our EV Future

Although many automakers have successfully built a solid-state battery in laboratory conditions, scaling up to mass-produce them has proven challenging. The work requires an arid environment, which is difficult to maintain in a large factory.

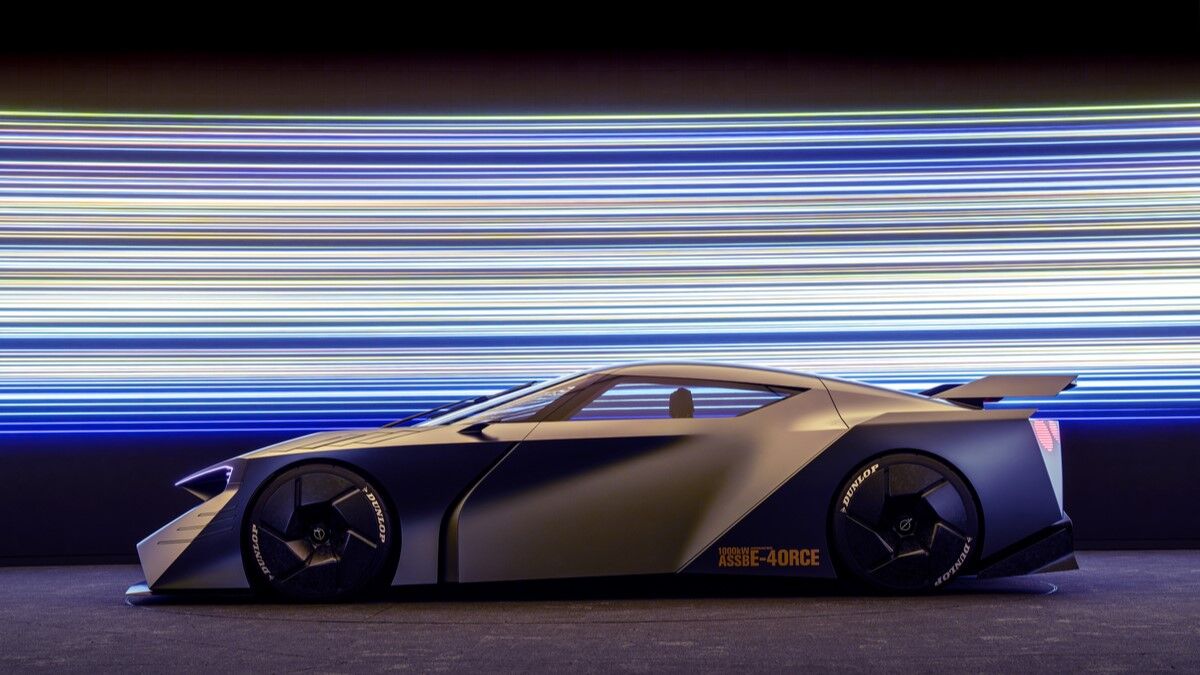

Nissan Claiming Dramatic Improvements, May Unveil Them with a Monster

- The company thinks it can build better batteries cheaper than the cost of today’s heavier cells

Engineers often discuss the progress of battery technology in terms of dollars per kWh. Experts have long maintained that EVs would reach cost parity with gas-powered cars when batteries cost around $100 per kWh.

InsideEVs reports that Nissan “is reportedly targeting a price of $75 per kWh, well below last year’s average pack price of $115 per kWh.” That could ultimately mean solid-state-powered EVs less expensive than today’s electric cars.

But the claims come from a troubled Nissan. The company has unsuccessfully sought merger partners to rescue it from dire financial straits. It recently canceled one of its only two EVs on the American market.

Rivals, meanwhile, are also working on solid-state tech, but are quieter about it. Both Stellantis and BMW have test vehicles on the road using the batteries today.