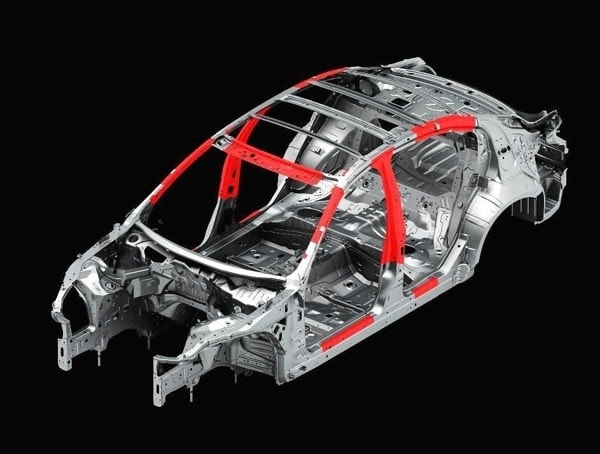

Seeking to improve the structural integrity of its new vehicles while helping boost fuel economy by reducing overall weight, Nissan Motor Company has announced it will transition to a new Advanced High Tensile Strength Steel (AHSS) for up to 25 percent of the total component set – by weight – in its future production models. The automaker plans to begin widespread implementation of this new efficiency initiative starting in 2017 with the goal of cutting curb weights by 15 percent when matching these new lower-mass parts with corresponding body structure design rationalization.

Also: 2013 Best Resale Value Award winners

The key to this trim-down process lies in the structure of the AHSS itself. Unlike many forms of high-strength steel that are hard to stamp into more complex shapes, the strain developed by Nissan has a "high formability" factor that allows it to be more easily – and inexpensively – worked both in during the creation of individual parts as well as when they are integrated into the vehicle as part of the normal production process.

Also: 10 Coolest Cars Under $25,000

First vehicle to benefit from the development and integration of Nissan’s new AAHS is the 2014 Infiniti Q50 model that will replace the current G37 when it goes on sale in the U.S. later this year.

You Might Also Like…

First Pics: All-new Cars for 2014

The 40 mpg Cars of 2013

5-Year Cost to Own Awards 2013