As Kelley Blue Book celebrates 100 years, we couldn’t resist looking back at the car that dominated the scene a century ago: the Ford Model T. From 1908-1927, Ford built and sold more than 15 million examples of the Model T. In the process, the company altered the automotive landscape forever with engineering and manufacturing innovations that reshaped how cars were made — and who could afford them. The Model T’s legacy still echoes in today’s modern vehicles.

From 1920-1926, the Model T accounted for nearly half of all automobile sales, making it the most popular car in America 100 years ago. Fast forward a century, and which vehicle now claims that kind of dominance? Ford still came out on top in the U.S. in 2025 with its F-series, but in electric vehicles (EVs), Tesla’s Model Y took the crown.

To get a clearer sense of the of the past century’s transformation, let’s explore which Model T ideas persist today in modern EVs like the Model Y. With the help of the California Automobile Museum’s Model T collection and the Pit Crew (the volunteer experts who maintain the museum’s collection), we identified several features and engineering principles that have evolved over the past century yet still show up today.

1926 models and 2026 models may look like utterly different cars, and in many ways, they are. However, a closer look reveals what has been preserved, refined, and reimagined to meet the demands of a changing world.

Left-Hand Drive Enters the Scene

The Model T shipped to its first customer on Oct. 1, 1908. One of its simplest and most striking features? Left-hand drive (sometimes called “left-hand steering”), with the operator seated on the left side of the vehicle. Early car models almost exclusively employed right-hand drive, with a few exceptions. For example, early Knox automobiles, circa 1900-1905, employed left-hand drive, though these cars used a tiller rather than a wheel. Left-hand drive works best for right-hand traffic, especially on bidirectional roads.

It wasn’t until the Model T, however, that left-hand drive became standard for American cars. The design made entering and exiting the car easier and safer. A century later, today’s Model Y may have sleeker door handles, but drivers still steer on the left, and passengers still step out onto the curb, not into traffic (though right-hand-drive models are available in countries like the United Kingdom and Japan that drive on the left).

Transmission Transformations

“One of the most interesting aspects of the Model T is the transmission,” said Richard Markwell, California Automobile Museum Model T expert and Pit Crew member. “It uses a planetary gear system, which is the gear system that’s very close to what you still have in your automatic transmission today.”

The Model T’s pioneering 2-speed transmission featured an outer ring gear, a central “sun” gear, and multiple “planet” gears working concurrently to provide a smoother shifting experience. Cotton or wood bands clamped around drums controlled the gear ratios. The Model T used a hand lever for throttle, and three foot pedals: one to shift between low/neutral/high, one for reverse, and one for braking.

Driving a Model T required constant manual input from the driver. Markwell, who also teaches Model T driving classes at the museum, explained that even drivers long-accustomed to modern manual transmissions have to adjust to the Model T’s unique control layout. “I had a ball with someone who’d been driving trucks all his life,” said Markwell. “He’d come up to a stop sign, and he’d push that clutch all the way down to be in neutral. Well, with this car, nope, he’s in low gear!” Don’t worry; Markwell assures us that once you get the hang of it, you can get your Tin Lizzie quite safely on down the road.

Jump ahead 100 years, and the transmission on a Model Y looks like something entirely new, but parts of its lineage trace back to early transmission innovation. The original Tesla Roadster shipped with multi-speed gearboxes, but they weren’t optimal. Over time, EVs gravitated toward fixed-gear, single-speed, direct-drive setups that better suit electric motors’ high-torque outputs. Now, no shifting is needed, and drivers can manage many settings automatically, often via a screen.

Differential Convergences and Divergences

To manage power distribution to the wheels during turns, both the Model T and Model Y employ differential gears. With 100 years between them, the implementations look different, but the core idea — allow left and right wheels to rotate at different speeds — remains virtually the same.

The Model T had an open rear-wheel differential assembly containing a ring-and-pinion set, axle shafts, and spider gears. This setup allowed the rear wheels to rotate at different speeds in a turn, but it could struggle on slippery surfaces, sending power to the wheel that had the least resistance. Some models used worm-gear differentials for increased power.

The Model Y evolves this piece of engineering while also using open differentials. Depending on the variant, this may apply to either or both axles. Tesla uses a sealed “drive unit” that houses the motor, gearbox, and differential together. It’s a highly computerized unit that manages torque efficiently, and the mechanical underpinnings of the differential aren’t worlds apart from their forebears in the Model T.

Getting in Shape: Body Evolution

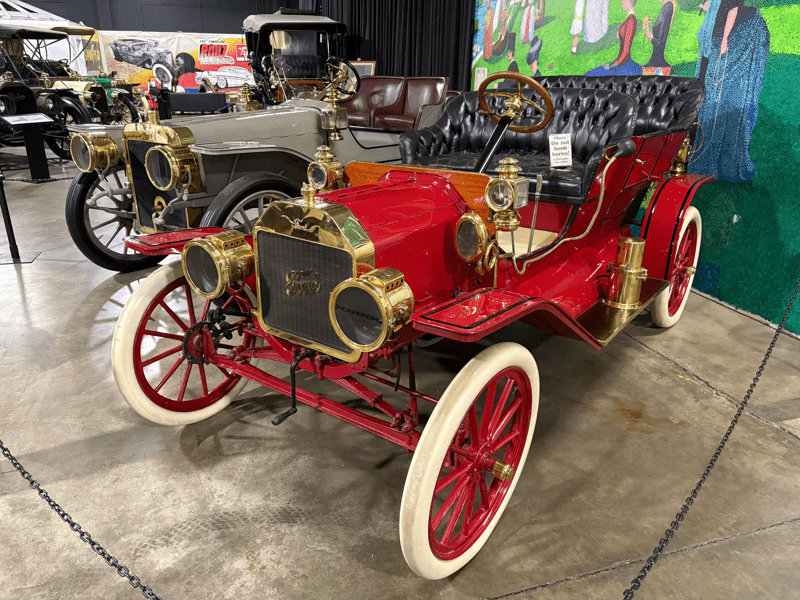

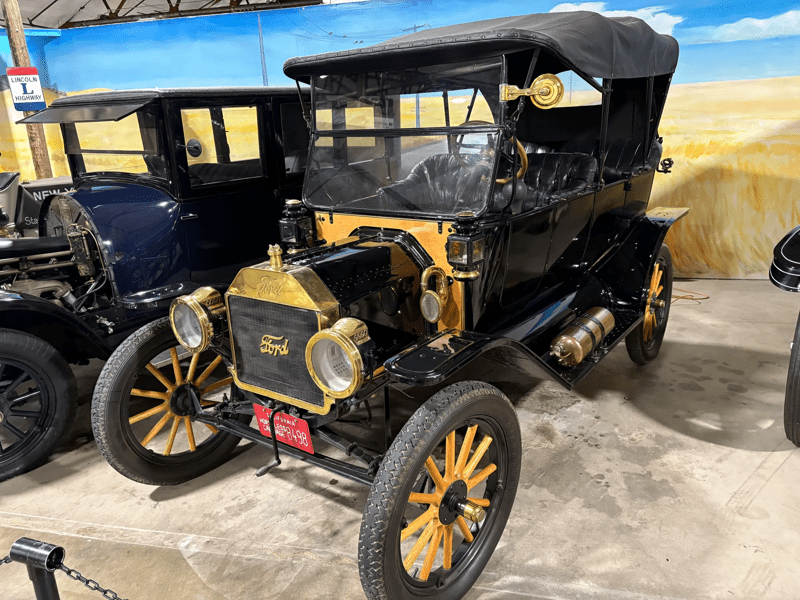

Early Model T examples primarily used wood framing and strong, lightweight vanadium-alloy steel body panels that could flex to absorb the bumps of rough roads. The cars also prominently featured brass in elements, including radiator shells, headlamps, and hubcaps, until about 1915.

As World War I began, materials were redirected to war efforts and munitions, effectively ending the Model T’s “Brass Era” and ushering in an era of black-painted steel parts. This also coincided with Ford’s famous line, “Any customer can have a car painted any color that he wants so long as it’s black.” Prior to 1914, the Model T had been available in a variety of paint colors.

While the Model Y uses very different materials, we can see a similar engineering philosophy to meet its needs. Where Ford used vanadium-alloy steel for its flexibility and affordability, Tesla uses a mix of lightweight aluminum and high-strength steel to achieve similar goals of reduced mass and improved safety.

Manufacturing, Mass Production, and Assembly Line

Ford built his first internal combustion engine in 1893. “They call it the ‘kitchen sink engine’ because he made it in his kitchen sink,” Markwell said. “From there, Ford failed at a number of business attempts until the Model T.” With that vehicle, Ford helped revolutionize automobile manufacturing and assembly.

In 1913, Ford created his moving assembly line, combining interchangeable parts, subdivided labor, and the movement of materials down the line. Consequently, the Model T, while undergoing modifications over the years, remained largely the same as its early models. “He really wanted to keep to the basics the same for as long as he could so that he could improve his profit margin on the automobile and keep the cost low for buyers,” Markwell said.

Ford was also known for contracting out certain parts to specialized suppliers who could stamp fenders or hoods, for example, rather than doing it in-house. It was relatively unheard of at the time, but by contracting out some parts to specialty suppliers, he cut costs dramatically. Henry Ford wanted to put the “Ford” in “affordability.” The productivity and price cuts enabled by these methods inspired wide adoption of his approach across the industry. A century later, mass-production logic and assembly-line methods remain the industry standard.

While Tesla has been exploring other assembly methods in recent years, most of the Model Y’s production life has still relied on moving assembly-line concepts, refining them with automation, and continually improving computerization. For example, the Model Y assembly line was reduced by about 10% by mounting the front seats and interior module onto the battery pack, which sits on the floor. The entire unit is then brought into the vehicle’s body from below. This method provides more room for teams to work on different parts of the car simultaneously.

With the Model T, Ford developed the blueprint that is still in use today and will continue to evolve alongside new milestones in manufacturing.

The Spirit of Innovation

Despite the century between them, Ford’s Model T and Tesla’s Model Y reshaped the automotive landscapes in which they reigned. A certain pioneering spirit dwells at the hearts of these behemoths of automotive engineering.

“Ford wanted the people who built the cars to be able to afford them,” said Markwell. “Most of the time before that, businesses didn’t care. They just wanted their prices higher and higher because it was feeding their table, not everybody else’s. Ford paid his people well, kept his prices down, and he did this partly by not mandating constant changes in production.”

It’s a vision that’s still relatable 100 years later, as it can feel harder to find consumers’ interests at the center of business practices. Ford shaped the Model T around the people for whom he was building it. In this simple mission, he created an automotive empire that remains dominant today.

Similarly, Tesla’s vision for EVs, particularly its Model Y, has radically altered the automotive industry. It has used Ford’s manufacturing methods as a springboard for innovations like “megacasting,” replacing dozens of parts with a single large cast aluminum piece to simplify production. Very recently, Ford has signaled that interest in similar casting (described as “unibody casting”) for its own next-generation EV efforts. The Model Y’s continuing advances have set the pace for many of its EV competitors.

Here’s to 100 More Years

There’s a century between them, but the Model T and the Model Y are two cars that helped to shape everything between and much of what’s to come. In the next 100 years, we hope the industry continues to fuse the motivations at the foundations of these two seminal models — a mission of affordability and a continuing push toward technological breakthroughs that will keep all of us driving safely and smoothly into the future.